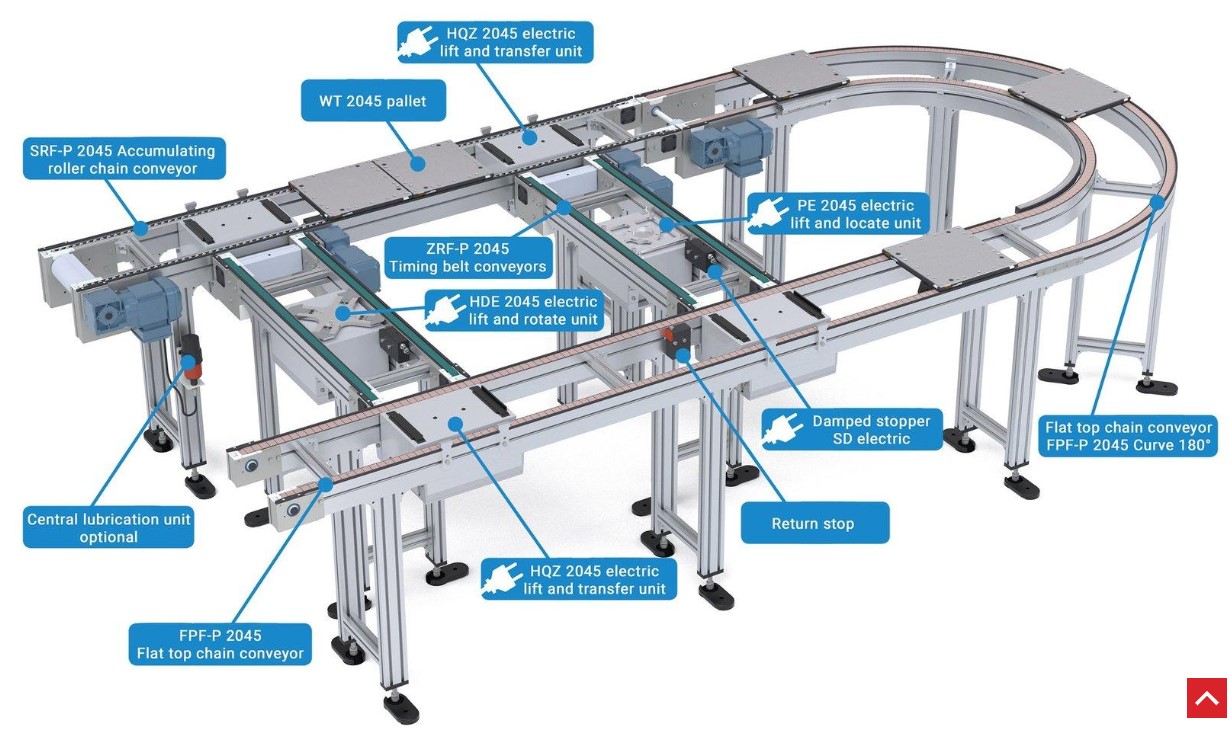

SPU 2040 - Accumulating Pallet Recirculation System

The SPU 2040 is an advanced pallet recirculation system that efficiently handles the automated and cost-effective tasks of dynamic feeding, buffering, positioning, and separating pallets, even in confined spaces. Featuring a durable design and a wide variety of configurable options, it is ideal for a broad range of automation and material handling applications.

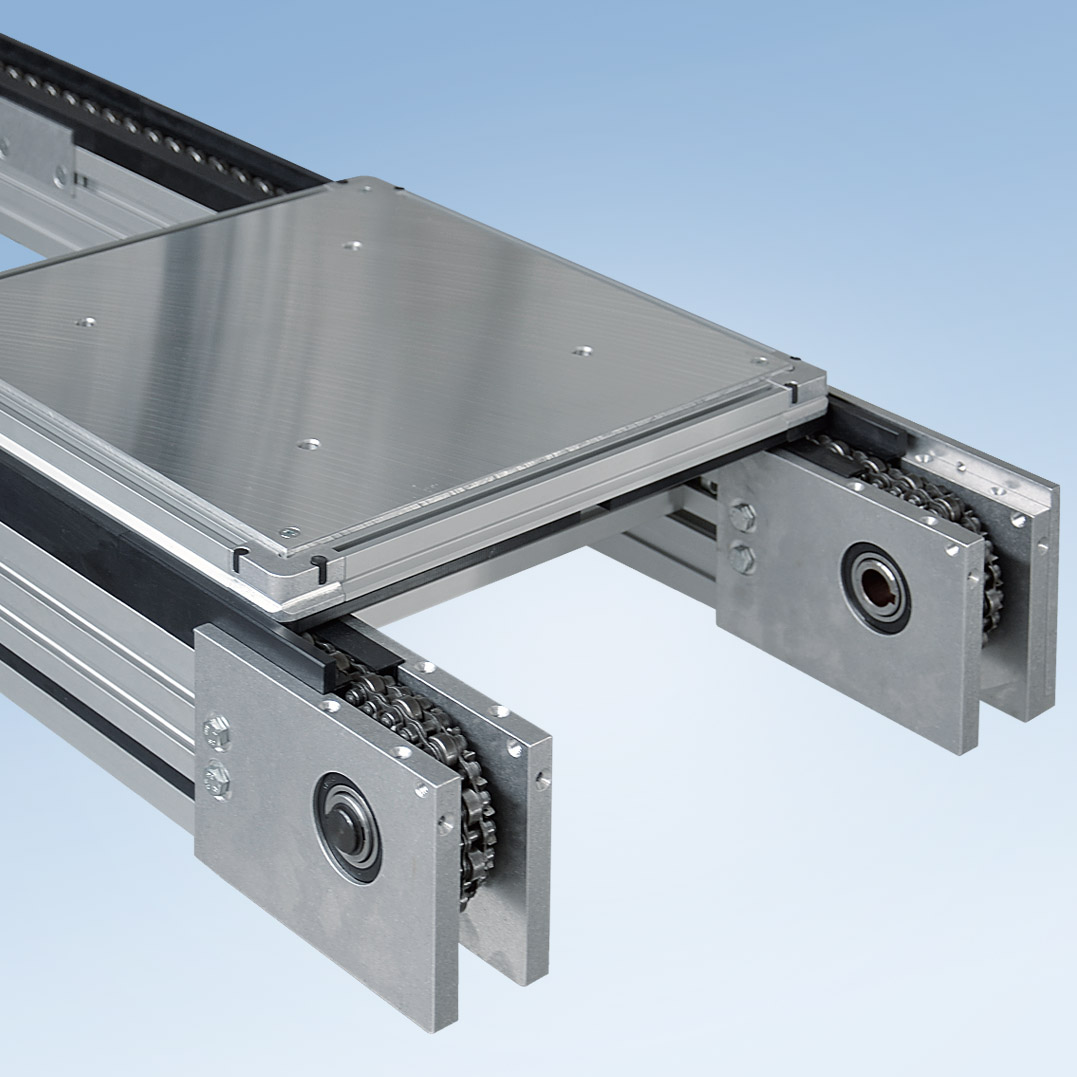

The SPU 2040 enables acyclic operation, functioning independently of the infeed cycle with automatic recirculation of workpiece carriers. Workpieces are transported along the upper transport level via the flat top chain. When a workpiece is removed, the empty carriers are safely guided around the tail and returned below the transport level. This ensures the carriers are ready at the start of the belt to be loaded with new workpieces, eliminating the need for a second conveyor level or complex control systems for lift-and-lower units. Additionally, there is no requirement for manual or automatic loading of workpiece carriers onto the belt.

Available as a single-line, dual-line or double line format.

Visit the AdaptTech Manufacturing Solutions Ltd website for more information on SPU 2040 - Accumulating Pallet Recirculation System