Plastic Pressure forming

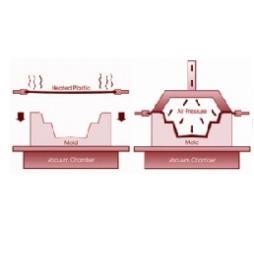

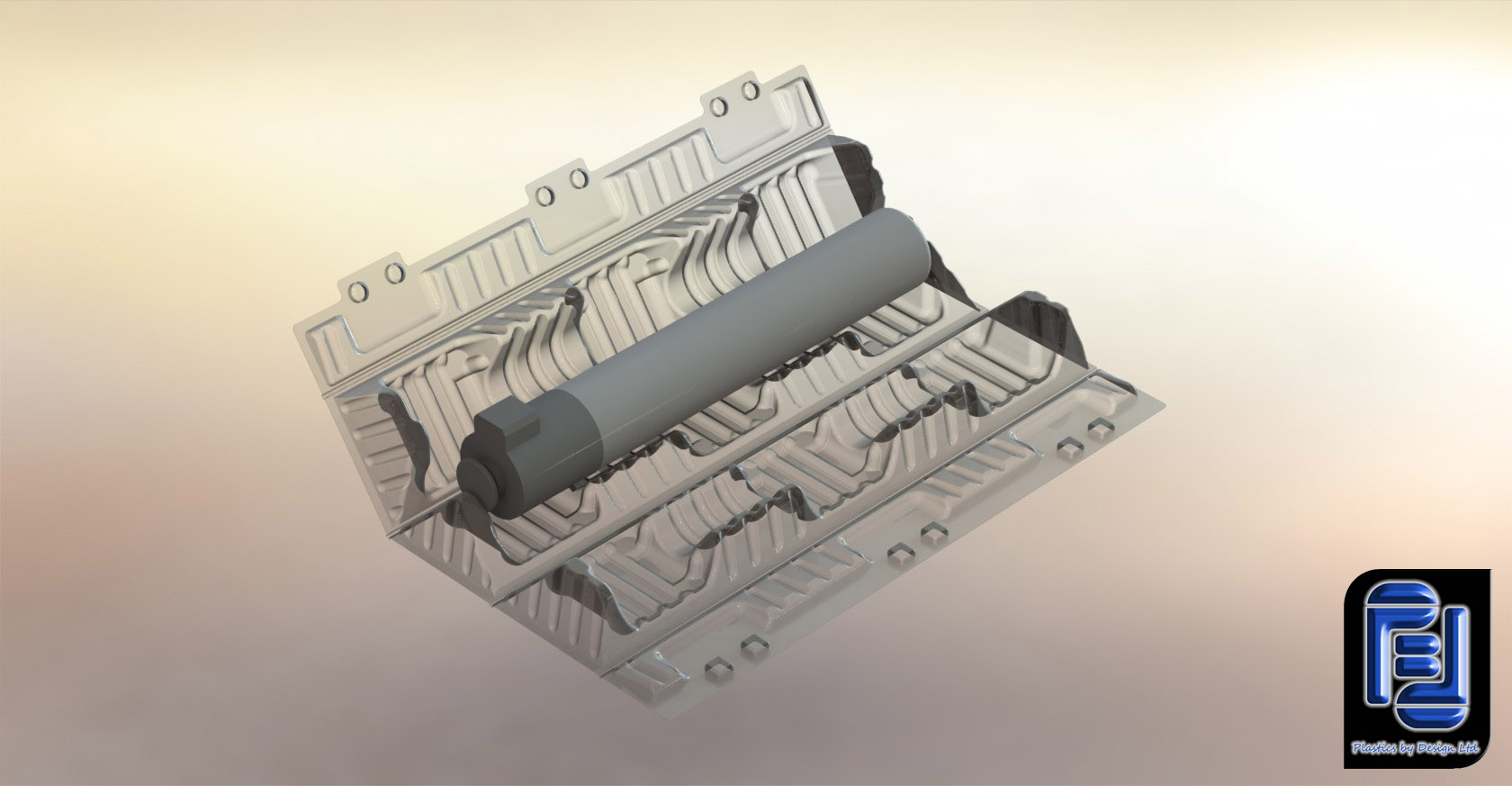

The difference between vacuum formings and pressure formings are clear in the end product: Pressure forming moulds have a great finish. Their surface texture is more defined and the corners of the moulds are sharper and more accurate to the original design. You can have certain textures or logos marked into the plastic surface, this cannot be done with vacuum forming. Pressure forming has the same quality of an injection moulding but the tooling costs are a lot less. Pressure forming is best suited to low to medium volume production in thick sheet. But can do thin sheet on a larger volume scale.Visit the Plastics By Design Ltd website for more information on Plastic Pressure forming