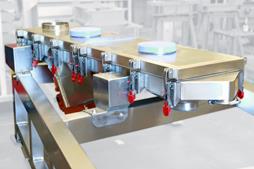

Electromagnetic Drive Feeders Now Available With Integral Hopper Outlet and Support Interface

03-11-2014

In response to recent customer requests Applied Vibration’s Electromagnetic Drive Feeders are now available with integral hopper outlet and support, providing an easier means of applying and mounting a vibrating feeder to a hopper containing loose bulk solids.

The design allows for a much simplified construction of hoppers which now require only a simple square mounting flange at their base.

When bolted in position the hopper outlet provides not only the correct geometry to discharge product into the vibrating feeder and ensure reliable mass flow, but also provides support for the vibrating feeder itself so no further steel work is required. The feeder is supported in such a way that the mounts are in compression and the feeder supported from beneath, making for a safer working installation.

A product depth regulation gate provides coarse adjustment to the depth of product flow, the control of the vibrating feeder then providing the accuracy of feed and virtually instantaneous stop start flow that make electromagnetic drive feeders the ideal choice for discharging, bagging plant, batching and weighing applications.

Feeders can be fitted with abrasion resistant steel liner plates for abrasive products such as glass or stone.Visit the Applied Vibration Ltd website for more information on Electromagnetic Drive Feeders Now Available With Integral Hopper Outlet and Support Interface