Heavy-duty encoder solution keeps cut lengths accurate, every time.

Background

Hipsher Tool & Die, Inc., of Wabash, IN specializes in custom fabrication and machinery. Starting as a one-man tool and die shop in 1946, Hipsher Tool & Die, Inc. has produced tools, dies, jigs, and molds.

Over the decades, they’ve expanded operations to include the design and fabrication of custom machinery, now their specialty. Customers range from walk-ins with small requests, to companies needing larger manufacturing systems.

The Problem

While developing a machine to cut cardboard, Hipsher’s testing revealed that the finished sheet length was varying over time.

The encoder providing length data to the cutting mechanism was missing counts occasionally, which resulted in finished length variations that were out of specification. The machine’s existing encoder and wheel system worked perfectly with other applications, but this particular material presented a challenge.

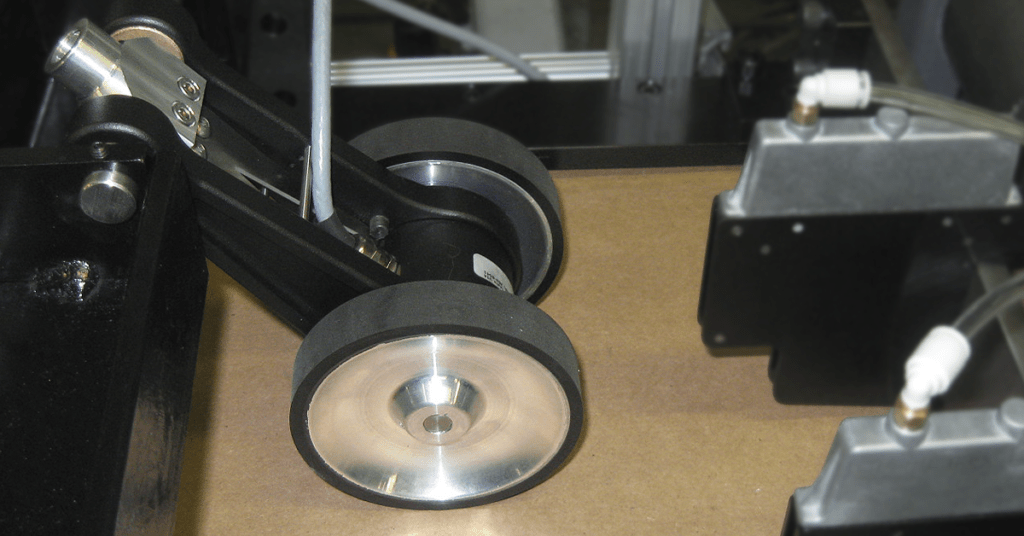

Further investigation revealed the cause: seams in the cardboard passing under the encoder wheel would cause the wheel to jump and lose contact with the surface.

The right encoder would need to be heavy enough to provide increased down-pressure to maintain contact with the cardboard being fed through, yet constructed with a material that would not damage the cardboard it came in contact with. The new encoder would also have to match the old encoder’s CPR and counts per inch.

The Solution

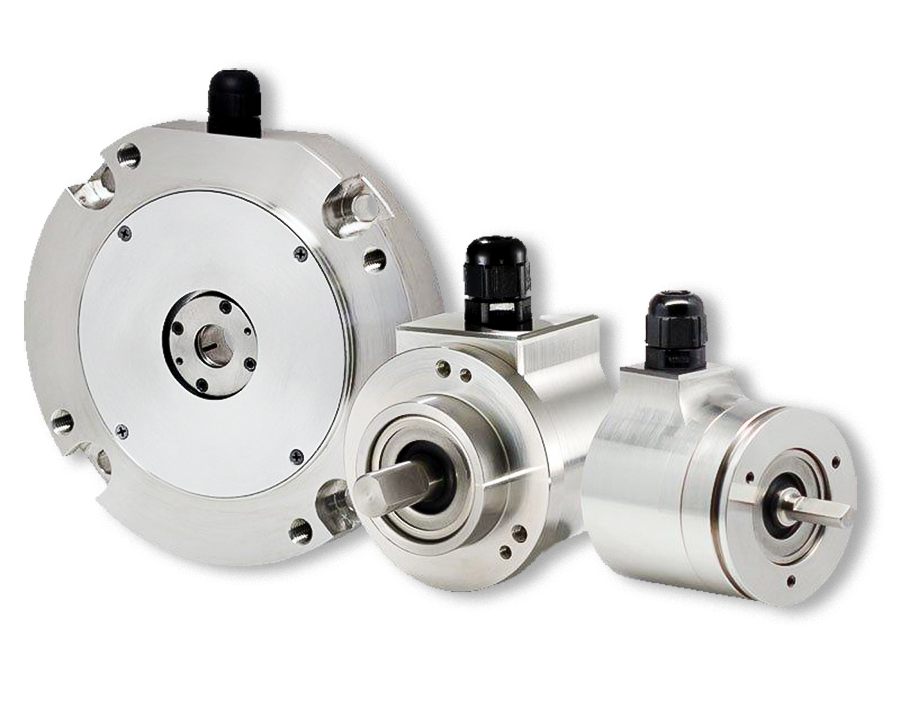

They contacted C&E Advanced Technologies, an Ohio distributor for Encoder Products Company. After consulting with EPC, C&E’s Sales Engineer Jeff Ligon recommended the Model TR3 Heavy Duty Tru-Trac® encoder.

The Model TR3 Heavy Duty Tru-Trac® encoder is an integrated encoder and spring-loaded, heavy-duty measuring wheel assembly all in one easy-to-use, compact unit. Available in a single or optional dual-wheel format, the Model TR3 Heavy Duty Tru-Trac® is a versatile solution for tracking velocity, position, or distance over a wide variety of surfaces in many industrial applications. Its spring-loaded torsion arm provides a simple-to-adjust torsion load, allowing the Model TR3 to be mounted in any orientation, even upside-down. The Model TR3 housing is an all-metal workhorse, specifically designed to take on your toughest application environments at operating speeds up to 3000 feet per minute.

The Model TR3’s sturdy all-metal housing and integrated spring-loaded pivot arm were key features that appealed to Eric Flory, the Hipsher Tool Engineering manager tasked with solving the problem. The heavier housing and stiff internal spring provided increased down pressure more than adequate to offset the “jolt” caused by the cardboard seams passing underneath the wheel. To avoid any damage to the cardboard, dual urethane 12” wheels were specified. Their encoders were also configured with a line drive output and CPR resolution that matched the previous encoder counts per inch.

After the Model TR3 encoder was installed and testing completed, Hipsher’s customer reported that the cut length was spot-on and production was up and running.

Find Out More

Do you have a question about which encoder is right for your application? When you contact EPC, you talk to engineers and encoder experts for your toughest encoder questions. You’ll get answers that make sense for your application.

With our industry-leading three-year warranty, if something does go wrong, we’ve got you covered.

Visit the British Encoder Products Company website for more information on Heavy-duty encoder solution keeps cut lengths accurate, every time.