Stainless Steel Encoders: Built for Industrial Challenges

In the world of manufacturing, where steam hisses, machinery clanks, and the air often carries the distinct scents of production, some components work silently in the background to keep everything running smoothly. Among these hidden parts are stainless steel encoders—those gleaming metal devices attached to automated equipment that rarely receive the recognition they deserve.

These encoders may not grab headlines, but for anyone who’s experienced the costly frustration of unexpected downtime, their value becomes immediately apparent.

Why Stainless Steel Makes the Difference

Factory environments present numerous challenges for sensitive equipment. Production floors are rarely gentle places—machinery endures vibration, impacts, and exposure to moisture and harsh chemicals. Standard components often struggle to withstand these conditions, leading to replacements that disrupt production and strain maintenance budgets.

This is where stainless steel encoders play the role, where their durability stands up to the physical demands of industrial settings. While conventional encoders might need replacement every few months in demanding environments, stainless steel counterparts often continue performing reliably for years.

The corrosion resistance particularly stands out in food and beverage processing facilities. In craft breweries, acidic cleaning solutions quickly deteriorate standard encoder housings, sometimes within weeks. Stainless versions withstand these same cleaning regimens year after year without significant degradation.

Beyond Durability: Additional Benefits

For food and pharmaceutical manufacturers, stainless steel encoders offer benefits beyond durability. Their non-porous surfaces resist harboring bacteria, reducing potential contamination sources—critical in industries where a single recall can have devastating consequences.

Temperature variation presents another challenge in factories. In facilities with poor insulation, conditions can range from near freezing to sweltering. Stainless steel encoders maintain consistent performance across this spectrum, providing reliable feedback regardless of seasonal shifts.

The true value becomes most evident when considering downtime costs. Every minute a production line sits idle represents lost revenue and missed deadlines. Components that cost more initially but deliver superior reliability ultimately prove more economical, embodying “buy once, cry once.”

Versatility Across Applications

The versatility of stainless steel encoders adds to their appeal. Available in both incremental configurations for basic positioning and absolute versions for complex motion control, they integrate into virtually any automated system. From delicate pharmaceutical equipment to industrial-scale mixers handling tons of material, these devices perform admirably across applications.

For facilities facing harsh conditions, frequent washdowns, or stringent hygiene requirements, stainless steel encoders represent a sound investment. While not the most visible components in an automation system, they often prove among the most valuable—precisely because they require so little attention.

Spotlight on British Encoder Products’ Industrial Solutions

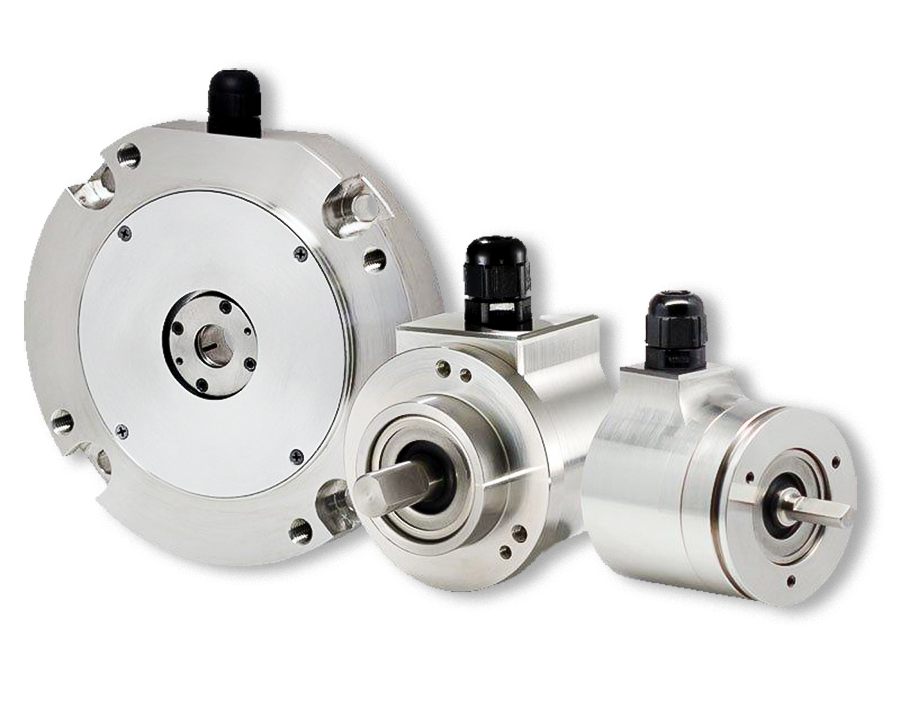

To illustrate these points, let’s examine three standout stainless steel encoder models from British Encoder Products Company’s catalogue.

Model 858: Standard Size with Exceptional Durability

The Model 858 is a heavy-duty 58mm diameter encoder for harsh factory and food industry environments. Manufactured from food-grade 316 stainless steel, this rugged yet compact encoder features resolutions up to 30,000 PPR, 36kg maximum shaft loading, double-shielded bearings, and optional IP65 sealing with high-temperature operation up to 100°C.

Model 865T: C-Face Thru-Bore Excellence

The Model 865T mounts directly on NEMA C-face motors with a slim 25.4mm profile. Unlike many C-face kit encoders, it includes precision bearings and internal flex mount to eliminate failures from shaft runout, advanced Opto-ASIC technology for noise immunity, resolutions up to 4096 PPR, and IP66 sealing when properly mounted.

Model 802S: Rugged Stainless Steel Solution

The Model 802S is a heavy-duty 50.8mm diameter encoder housed in type 316 stainless steel, designed specifically for harsh industrial environments. With resolutions up to 30,000 PPR, 35kg maximum shaft loading, and available IP67 sealing, this compact encoder excels in applications where exposure to caustic chemicals or contamination is a concern. The 802S offers multiple mounting options and can operate in temperatures up to 100°C with the high-temperature option, making it ideal for food processing, robotics, and material handling applications.

Conclusion

For engineers seeking components that withstand industrial rigors while delivering consistent performance, stainless steel encoders represent an investment in production reliability. Their extended service life and reduced maintenance needs typically result in lower total ownership costs and fewer production interruptions—essential in today’s competitive manufacturing landscape.

The next time production targets are met without interruption, spare a thought for these unassuming devices. In manufacturing, sometimes the most important components are the ones quietly doing their jobs day after day, without fanfare or recognition.

Visit the British Encoder Products Company website for more information on Stainless Steel Encoders: Built for Industrial Challenges