Surface Finish Influences At Moontown Ltd

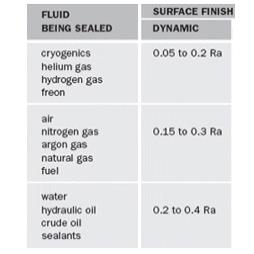

***DYNAMIC:*** - The quality of the surface finish influences the relative wear of the cover material. The transfer of a thin film of PTFE from the seal cover to the mating dynamic surface will improve seal life. Relatively rough finishes wear the cover material too rapidly, too smooth surfaces result in insufficient material transfer to form a thin film. - As general rule, the higher the sealing surface hardness the better the seal performance. Higher hardness reduces wear and increases seal life. A 40 HRC or higher is recommended for slow to moderate movements. The ideal hardness is between 60 and 70 HRC.Visit the Moontown Ltd website for more information on Surface Finish Influences At Moontown Ltd