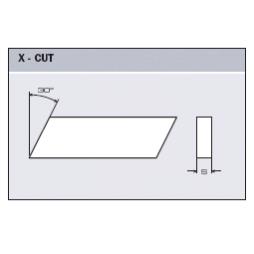

Wear Rings Cut Styles

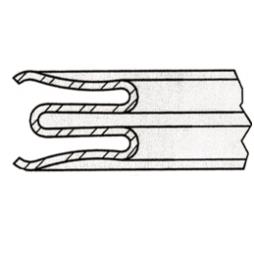

- Bearing capacities are given for speeds up to 1.5 m/s, Above this value, consult Moontown. Moontown wear rings can be used in all hydraulic oil media. - PTFE materials have a low coefficient of friction but also low load characteristics. They are therefore more suitable for low load applications. - Thermoplast materials have a higher friction coefficient but also high load characteristics, and can be used in high pressure. - Wear rings are made with different cuts: x for reciprocating, y for rotary and z for reciprocating or rotary movements in contaminated systems to protect the seal. - In extremely contaminated systems, consideration should be given to the use of code 99 material position inboard of the seal with any other wear ring material situated in the outboard position if needed.Visit the Moontown Ltd website for more information on Wear Rings Cut Styles