Basic vacuum formed packaging

12-06-2024

Vacuum formed packaging, also known as thermoformed packaging, is a manufacturing process used to create a variety of plastic products, including packaging materials. Here's an overview of the process and its benefits:

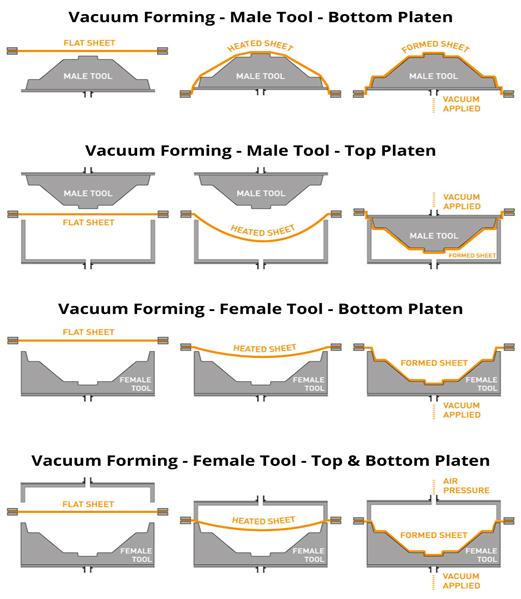

Process.

- Heating: A plastic sheet is heated until it becomes pliable.

- Forming: The heated plastic sheet is placed over a tool.

- A vacuum is then applied, pulling the plastic tightly against the tool, creating the desired shape.

- Cooling: The formed plastic is cooled to retain the shape.

- Trimming: The excess plastic is trimmed off, leaving the final product.

Materials Used Common materials used in vacuum forming include:

- Polyethylene (PE)

- Polypropylene (PP)

- Polystyrene (PS)

- Polyvinyl Chloride (PVC)

- Polyethylene Terephthalate (PET)

Applications Vacuum formed packaging.

Its used across various industries due to its versatility and cost-effectiveness. Some common applications include:

- Blister packs: Often used for pharmaceuticals, electronics, and small consumer goods.

- Clamshell packaging: Used for food products, electronics, and other retail items.

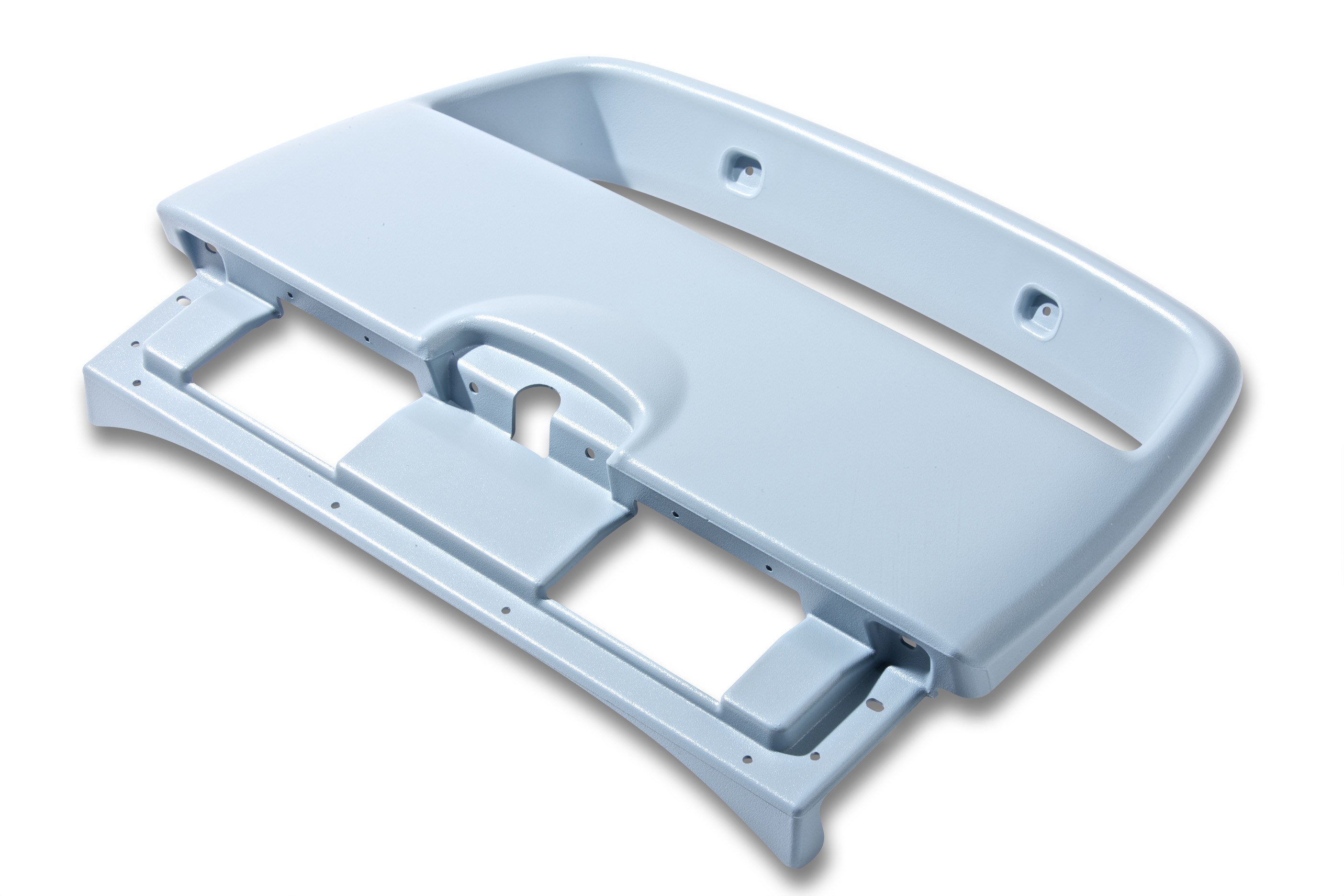

- Trays: Used in food services, medical equipment, and industrial components transit trays.

- Custom packaging solutions: Tailored to specific products for protection and display purposes.

Benefits

- Cost-Effective: The process is generally less expensive than other moulding methods, especially for small to medium production runs.

- Quick Turnaround: The moulds for vacuum forming can be produced relatively quickly, enabling faster production times.

- Design Flexibility: Allows for a wide range of shapes and sizes, making it suitable for custom packaging solutions.

- Durability and Protection: Provides excellent protection for products during shipping and handling.

- Visibility: Transparent materials can be used, which is beneficial for retail displays where product visibility is important.

Environmental Considerations

- Recyclability: Many of the materials used in vacuum forming are recyclable.

- Sustainability: Efforts are being made to use more eco-friendly materials and processes to reduce the environmental impact.

Overall, vacuum formed packaging is a versatile and efficient solution for many packaging needs, offering both functional and aesthetic benefits.

www.vacforming.uk.com

Visit the Plastics By Design Ltd website for more information on Basic vacuum formed packaging