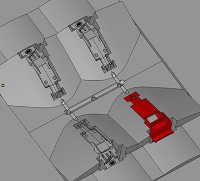

In-house toolmaking

For more information on In-house toolmaking please contact us.The quality of an injection moulded component depends on both good component design and the accuracy of the mould tool. Over many years, we have gained a reputation for manufacturing precision engineered tooling to the highest quality and accuracy. Delivering engineering excellence through investment in our people and equipment.Our capabilities range from the simplest open and shut tools, to multi-impression auto-unscrewing tools. Tooling is manufactured using the finest tool steels and the latest CAD/ CAM software.In fact, we are so confident in the quality of our tooling that we provide a ten-year no maintenance guarantee for tools we design, manufacture and mould. (Excluding magnet tooling)We offer a proactive approach to project management, from component design through to tool manufacture, sampling and volume production.Due to the aggressive nature of the magnetic material, good tool maintenance is key to the lifespan of the tool and quality of the components. Being able to offer this service in-house enhances the productivity of a magnet mould tool.

Visit the Andel Plastics Ltd website for more information on In-house toolmaking