Injection Mould Tool Manufacture

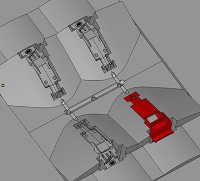

For more information on Injection Mould Tool Manufacture please contact us.The quality of an injection moulded component not only depends on the design of the component, but also from the design and accuracy of the mould tool. At Andel Plastics we have an in-house toolroom, fully equipped with the latest in CNC machining centres, wire eroders, spark eroders and complemented by jig grinders, surface grinders, CNC lathes etc. We like to be involved in a project from initial component concept working closely with our customers to understand their requirements and provide effective solutions. With expert knowledge we can advise on design improvements, material specifications, manufacture of prototype tooling, right through to single impression and multi-cavity hot runner system tooling. We specialise in offering solutions to complex problems and have vast experience in design and manufacture of auto unscrewing mechanisms, core pulling, collapsing cores, insert and over moulding tools. With the added advan age of an in-house moulding facility the tooling manufacture, sampling, modification and final production runs can be done under one roof, with the effect of reduced lead times minimal downtimes on repairs and maintenance whilst providing a cost effective service. If Andel Plastics manufactures a tool and then moulds in-house from this tool - the maintenance of the tool is included for ten years. We also offer tool refurbishment, repair and modification services.

Visit the Andel Plastics Ltd website for more information on Injection Mould Tool Manufacture